Tare da yawan jan ƙarfe a cikin nau'ikan kayayyakin masana'antu daban-daban, ana ɗaukar jan ƙarfe a matsayin abu mai amfani sosai.

Ana samar da foil ɗin tagulla ta hanyar takamaiman hanyoyin ƙera su a cikin injin niƙa foil ɗin, wanda ya haɗa da birgima mai zafi da sanyi.

Tare da aluminum, ana amfani da jan ƙarfe sosai a cikin kayayyakin masana'antu a matsayin kayan aiki mai matuƙar amfani a tsakanin kayan ƙarfe marasa ƙarfe. Musamman a cikin 'yan shekarun nan, buƙatar jan ƙarfe ta yi ta ƙaruwa ga kayayyakin lantarki, ciki har da wayoyin hannu, kyamarorin dijital, da na'urorin IT.

Ƙirƙirar foil

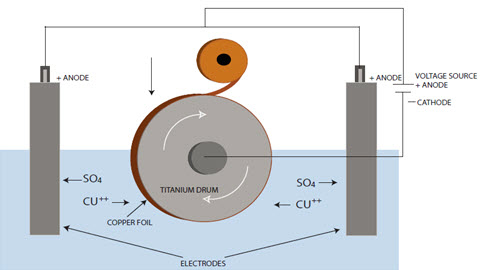

Ana samar da siririn foils na jan ƙarfe ta hanyar sanya wutar lantarki ko kuma birgima. Don sanya wutar lantarki, dole ne a narkar da jan ƙarfe mai inganci a cikin acid don samar da wutar lantarki ta jan ƙarfe. Ana tura wannan maganin electrolyte zuwa cikin ganguna masu juyawa waɗanda aka nutse a cikin wani ɓangare waɗanda aka caji ta hanyar lantarki. A kan waɗannan ganguna, an saka siririn fim na jan ƙarfe a cikin wutar lantarki. Wannan tsari kuma ana kiransa plating.

A cikin tsarin kera jan ƙarfe mai amfani da wutar lantarki, ana sanya foil ɗin jan ƙarfe a kan ganga mai juyawa daga titanium daga maganin jan ƙarfe inda aka haɗa shi da tushen wutar lantarki na DC. Ana haɗa cathode ɗin da ganga kuma ana nutsar da anode ɗin a cikin maganin jan ƙarfe mai amfani da wutar lantarki. Lokacin da aka yi amfani da filin lantarki, ana sanya jan ƙarfe a kan ganga yayin da yake juyawa a hankali. Fuskar jan ƙarfe a gefen ganga tana da santsi yayin da gefen da ke gefe yake da tauri. Yayin da saurin ganga ya yi ƙasa, jan ƙarfen ya yi kauri kuma akasin haka. Ana jawo jan ƙarfen kuma yana taruwa a saman cathode na ganga mai amfani da wutar lantarki. Gefen matte da ganga na foil ɗin jan ƙarfe suna wucewa ta hanyoyi daban-daban na magani don jan ƙarfen ya dace da ƙera PCB. Magungunan suna haɓaka mannewa tsakanin tagulla da dielectric interlayer yayin aikin lamination na jan ƙarfe. Wata fa'idar jiyya ita ce yin aiki azaman masu hana tarnish ta hanyar rage iskar shaka ta tagulla.

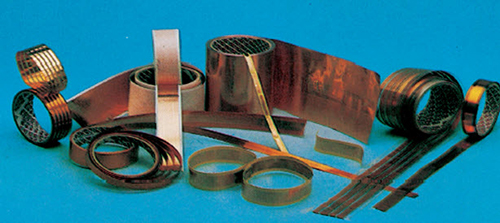

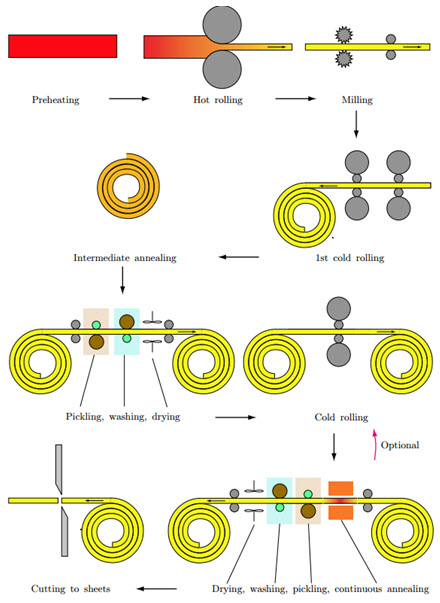

Hoto na 1:Tsarin Kera Tagulla Mai Lalacewa ta Wutar Lantarki Hoto na 2 yana nuna hanyoyin kera kayayyakin jan ƙarfe da aka naɗe. Kayan aikin birgima an raba su kusan zuwa nau'i uku; wato, injinan birgima masu zafi, injinan birgima masu sanyi, da injinan foil.

Ana samar da na'urorin siririn foils kuma ana yin maganin sinadarai da na inji daga baya har sai sun zama siffarsu ta ƙarshe. An ba da taƙaitaccen bayani game da tsarin birgima na foils na jan ƙarfe a cikin Hoto na 2. Ana dumama tubalin jan ƙarfe mai siminti (kimanin girma: 5mx1mx130mm) har zuwa 750°C. Sannan, ana birgima shi da zafi a matakai da yawa zuwa 1/10 na kauri na asali. Kafin birgima ta farko a sanyi, ana cire sikelin da ya samo asali daga maganin zafi ta hanyar niƙa. A cikin tsarin birgima na sanyi, kauri yana raguwa zuwa kusan 4 mm kuma ana samar da zanen gado zuwa na'urori. Ana sarrafa tsarin ta yadda kayan zai ƙara tsayi kuma ba zai canza faɗinsa ba. Ganin cewa ba za a iya ƙara samar da zanen gado a wannan yanayin ba (kayan sun taurare sosai) suna yin maganin zafi kuma ana dumama su zuwa kusan 550°C.

Lokacin Saƙo: Agusta-13-2021