Masana'antar kayan PCB ta ɓatar da lokaci mai yawa wajen ƙirƙirar kayan da ke samar da ƙarancin asarar sigina. Don ƙirar manyan gudu da mita mai yawa, asarar za ta iyakance nisan yaɗa sigina kuma ta ɓata sigina, kuma za ta haifar da karkacewar juriya wanda za a iya gani a cikin ma'aunin TDR. Yayin da muke tsara kowane allon da'ira da aka buga da kuma haɓaka da'irori waɗanda ke aiki a mafi yawan mitoci, yana iya zama jaraba a zaɓi jan ƙarfe mafi santsi a cikin duk ƙirar da kuka ƙirƙira.

Duk da cewa gaskiya ne cewa taurin jan ƙarfe yana haifar da ƙarin karkacewa da asara, yaya zanen jan ƙarfe ɗinku yake buƙatar santsi? Akwai wasu hanyoyi masu sauƙi da za ku iya amfani da su don shawo kan asara ba tare da zaɓar jan ƙarfe mai santsi ba ga kowane ƙira? Za mu duba waɗannan batutuwa a cikin wannan labarin, da kuma abin da za ku iya nema idan kun fara siyan kayan PCB.

Nau'ikanPCB Copper Foil

Yawanci idan muka yi magana game da jan ƙarfe akan kayan PCB, ba ma magana game da takamaiman nau'in jan ƙarfe ba, muna magana ne kawai game da ƙaiƙayinsa. Hanyoyi daban-daban na adana jan ƙarfe suna samar da fina-finai masu ƙimar ƙaiƙayi daban-daban, waɗanda za a iya bambanta su a cikin hoton na'urar duba na'urar lantarki (SEM). Idan za ku yi aiki a manyan mitoci (yawanci 5 GHz WiFi ko sama da haka) ko a manyan gudu, to ku kula da nau'in jan ƙarfe da aka ƙayyade a cikin takardar bayanai ta kayan ku.

Haka kuma, tabbatar da fahimtar ma'anar ƙimar Dk a cikin takardar bayanai. Kalli wannan tattaunawar podcast tare da John Coonrod daga Rogers don ƙarin koyo game da ƙayyadaddun bayanai na Dk. Da wannan a zuciya, bari mu kalli wasu nau'ikan foil ɗin jan ƙarfe na PCB daban-daban.

An cire wutar lantarki

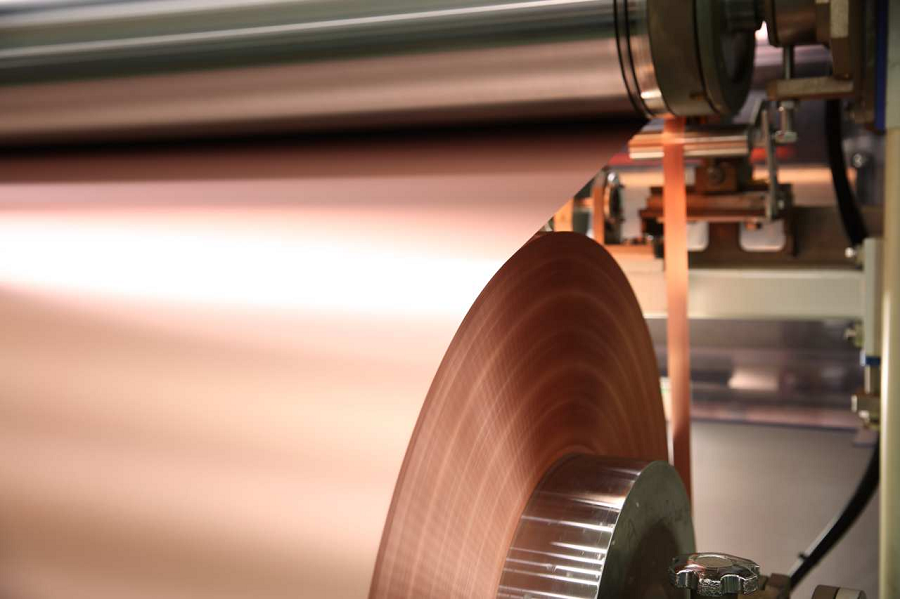

A cikin wannan tsari, ana juya ganga ta hanyar maganin electrolytic, kuma ana amfani da hanyar mayar da wutar lantarki don "girma" takardar jan ƙarfe a kan ganga. Yayin da ganga ke juyawa, ana naɗe fim ɗin jan ƙarfe a hankali a kan abin naɗi, yana ba da takardar jan ƙarfe mai ci gaba wanda daga baya za a iya naɗe shi a kan laminate. Gefen ganga na jan ƙarfe zai dace da ƙaiƙayin ganga, yayin da gefen da aka fallasa zai fi tauri.

An yi amfani da takardar jan ƙarfe ta PCB mai amfani da wutar lantarki

Samar da jan ƙarfe mai narkewa ta hanyar lantarki.

Domin a yi amfani da shi a tsarin ƙera PCB na yau da kullun, za a fara haɗa gefen tagulla mai kauri da wani sinadari mai kama da resin. Sauran jan ƙarfe da aka fallasa (gefen ganguna) za a buƙaci a yi masa ƙauri da gangan ta hanyar sinadarai (misali, tare da etching na plasma) kafin a yi amfani da shi a tsarin lamination na jan ƙarfe na yau da kullun. Wannan zai tabbatar da cewa za a iya haɗa shi da wani Layer na gaba a cikin PCB stackup.

Tagulla Mai Tsabtace Wutar Lantarki da Aka Yi Wa Kulawa a Sama

Ban san mafi kyawun kalma da ta ƙunshi dukkan nau'ikan saman da aka yi wa magani bafoils na jan ƙarfe, don haka taken da ke sama. Waɗannan kayan jan ƙarfe an fi sanin su da foils masu juye-juye, kodayake akwai wasu bambance-bambance guda biyu (duba ƙasa).

Faifan da aka yi wa magani na baya suna amfani da maganin saman da aka shafa a gefen santsi (gefen ganga) na takardar jan ƙarfe mai siffar lantarki. Layer ɗin magani kawai siririn shafi ne wanda ke tauri jan ƙarfe da gangan, don haka zai sami ƙarin mannewa ga kayan dielectric. Waɗannan jiyya kuma suna aiki azaman shingen iskar shaka wanda ke hana tsatsa. Lokacin da aka yi amfani da wannan jan ƙarfe don ƙirƙirar bangarorin laminate, gefen da aka yi wa magani yana ɗaurewa da dielectric, kuma ɓangaren da ya rage mai tauri ya kasance a bayyane. Gefen da aka fallasa ba zai buƙaci ƙarin tauri ba kafin a yi masa fenti; zai riga ya sami isasshen ƙarfi don haɗawa da Layer na gaba a cikin PCB stackup.

Bambance-bambancen guda uku akan takardar jan ƙarfe da aka yi wa magani sun haɗa da:

Foil ɗin jan ƙarfe mai tsayin zafin jiki (HTE): Wannan foil ɗin jan ƙarfe ne mai siffar lantarki wanda ya dace da ƙa'idodin IPC-4562 Grade 3. Ana kuma yi wa fuskar da aka fallasa magani da shingen iskar shaka don hana tsatsa yayin ajiya.

Foil ɗin da aka yi wa magani sau biyu: A cikin wannan foil ɗin jan ƙarfe, ana shafa maganin a ɓangarorin biyu na fim ɗin. Wani lokaci ana kiran wannan kayan foil ɗin da aka yi wa magani a gefen drum.

Tagulla mai jurewa: Ba a saba rarraba wannan a matsayin tagulla da aka yi wa fenti da saman ba. Wannan tagulla yana amfani da wani shafi na ƙarfe a kan gefen tagulla mai matte, wanda daga nan sai a yi tauri har zuwa matakin da ake so.

Aiwatar da maganin saman a cikin waɗannan kayan jan ƙarfe abu ne mai sauƙi: ana birgima foil ɗin ta hanyar ƙarin baho na electrolyte waɗanda ke shafa faranti na jan ƙarfe na biyu, sannan sai a bi ta da wani Layer na tsaba mai shinge, sannan a ƙarshe a yi amfani da Layer na fim mai hana datti.

PCB jan ƙarfe foil

Tsarin maganin saman foils na jan ƙarfe. [Tushe: Pytel, Steven G., da sauransu. "Binciken maganin jan ƙarfe da tasirin yaɗuwar sigina." A cikin taron Kayan Lantarki da Fasaha na 58th na 2008, shafi na 1144-1149. IEEE, 2008.]

Tare da waɗannan hanyoyin, kuna da kayan da za a iya amfani da su cikin sauƙi a cikin tsarin ƙera allon yau da kullun tare da ƙaramin ƙarin sarrafawa.

Tagulla Mai Naɗewa

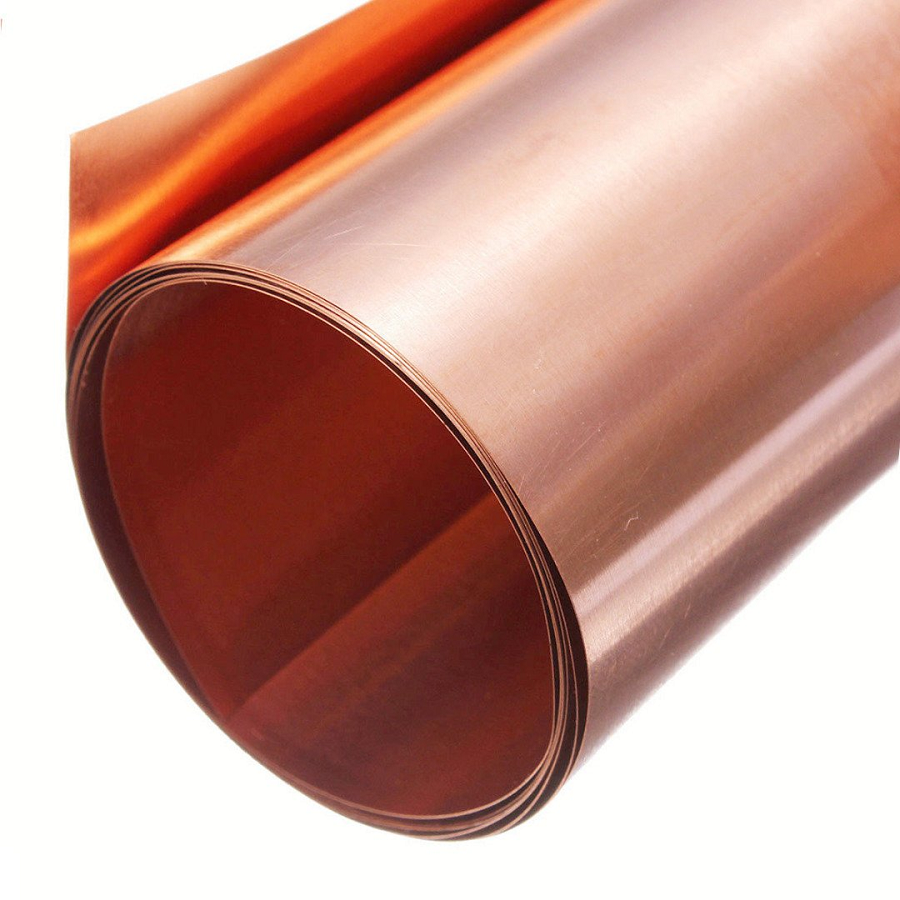

Faifan tagulla da aka yi birgima za su ratsa birgiman foil ɗin tagulla ta cikin birgiman guda biyu, wanda zai naɗe takardar tagulla cikin sanyi zuwa kauri da ake so. Ƙarfin takardar foil ɗin da aka samu zai bambanta dangane da sigogin birgima (gudun, matsin lamba, da sauransu).

Takardar da aka samo za ta iya zama mai santsi sosai, kuma ana iya ganin striations a saman takardar jan ƙarfe da aka naɗe. Hotunan da ke ƙasa suna nuna kwatancen tsakanin takardar jan ƙarfe da aka naɗe da wutar lantarki da kuma takardar jan ƙarfe da aka naɗe.

Kwatanta takardar jan ƙarfe ta PCB

Kwatanta foils ɗin da aka kunna ta hanyar lantarki da kuma waɗanda aka kunna ta hanyar birgima.

Tagulla Mai Ƙarancin Bayani

Wannan ba lallai bane wani nau'in foil na jan ƙarfe da za ku ƙera da wani tsari daban. Tagulla mai ƙarancin fasali jan ƙarfe ne mai amfani da lantarki wanda ake shafawa kuma aka gyara shi da tsarin ƙaramin-rufe don samar da ƙarancin matsakaicin rufewa tare da isasshen rufewa don mannewa ga substrate. Tsarin kera waɗannan foil ɗin jan ƙarfe yawanci mallakar mallakar ne. Waɗannan foil ɗin galibi ana rarraba su azaman ultra-low profile (ULP), very low profile (VLP), da kuma low-profile kawai (LP, kimanin 1 micron matsakaicin rufewa).

Labarai masu alaƙa:

Me yasa ake amfani da jan ƙarfe a cikin masana'antar PCB?

An Yi Amfani da Tagulla a Cikin Allon Da'ira da Aka Buga

Lokacin Saƙo: Yuni-16-2022