Takardar jan ƙarfeyana da ƙarancin iskar oxygen a saman kuma ana iya haɗa shi da nau'ikan abubuwa daban-daban, kamar ƙarfe, kayan rufewa. Kuma ana amfani da foil ɗin jan ƙarfe galibi a cikin kariyar lantarki da antistatic. Don sanya foil ɗin jan ƙarfe mai sarrafawa akan saman substrate kuma a haɗa shi da foil ɗin ƙarfe, zai samar da kyakkyawan ci gaba da kariyar lantarki. Ana iya raba shi zuwa: foil ɗin jan ƙarfe mai manne kansa, foil ɗin jan ƙarfe na gefe ɗaya, foil ɗin jan ƙarfe na gefe biyu da makamantansu.

A cikin wannan nassi, idan za ku ƙara koyo game da foil ɗin jan ƙarfe a cikin tsarin kera PCB, da fatan za a duba kuma a karanta abubuwan da ke ƙasa a cikin wannan nassi don ƙarin ilimin ƙwararru.

Mene ne siffofin jan ƙarfe foil a cikin masana'antar PCB?

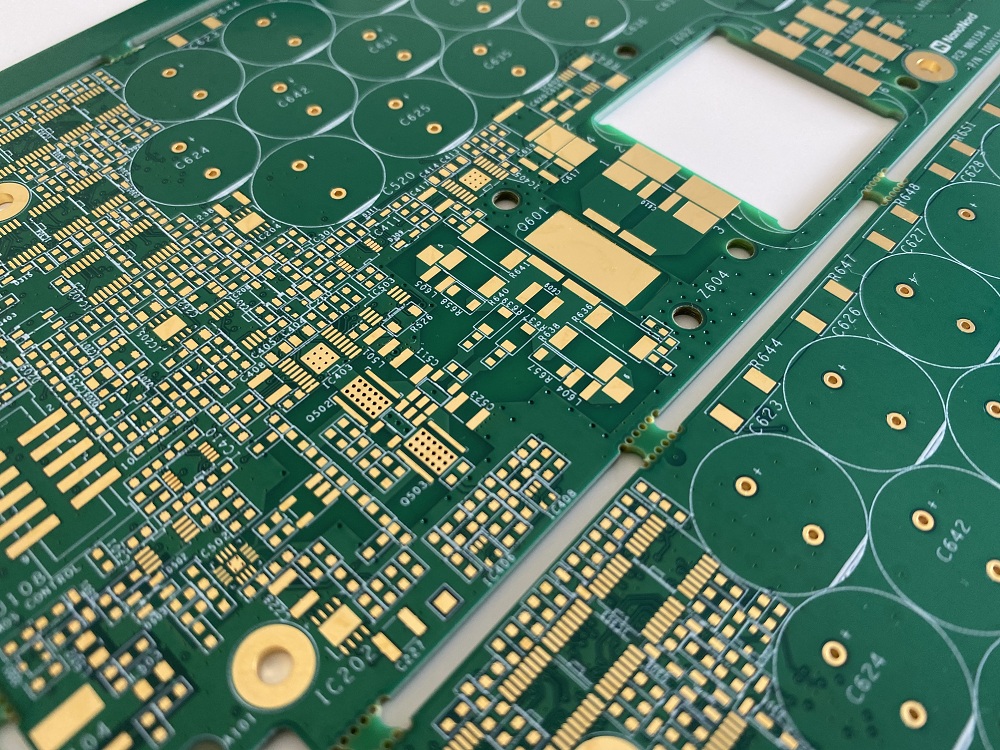

PCB jan ƙarfe foilshine kauri na farko da aka yi amfani da shi a kan yadudduka na waje da na ciki na allon PCB mai layuka da yawa. Ana bayyana nauyin tagulla a matsayin nauyin (a cikin oza) na tagulla da ke cikin murabba'in ƙafa ɗaya na yanki. Wannan siga yana nuna kauri gaba ɗaya na tagulla akan layin. MADPCB yana amfani da waɗannan nauyin tagulla don ƙera PCB (faranti na farko). An auna nauyin a oz/ft2. Ana iya zaɓar nauyin tagulla da ya dace don dacewa da buƙatun ƙira.

· A cikin kera PCB, foils ɗin jan ƙarfe suna cikin birgima, waɗanda aka yi su da kayan lantarki masu tsarki na 99.7%, kuma kauri na 1/3oz/ft2 (12μm ko 0.47mil) - 2oz/ft2 (70μm ko 2.8mil).

· Takardar jan ƙarfe tana da ƙarancin iskar oxygen a saman kuma masana'antun laminate na iya haɗa ta da kayan tushe daban-daban, kamar ƙarfe, polyimide, FR-4, PTFE da yumbu, don samar da laminates masu lulluɓe da tagulla.

· Haka kuma ana iya shigar da shi a cikin allon mai layi da yawa kamar foil ɗin tagulla kafin a danna shi.

· A cikin ƙera PCB na gargajiya, kauri na ƙarshe na tagulla a kan yadudduka na ciki na foil ɗin tagulla na farko; A kan yadudduka na waje muna yin farantin ƙarin jan ƙarfe 18-30μm akan hanyoyin yayin aikin rufin panel.

· Tagulla don yadudduka na waje na allunan layuka da yawa yana cikin siffar foil na tagulla kuma an matse shi tare da prepregs ko tsakiya. Don amfani da microvias a cikin HDI PCB, foil ɗin tagulla yana kan RCC (tagulla mai rufi da resin).

Me yasa ake buƙatar takardar jan ƙarfe a cikin masana'antar PCB?

Tsarin jan ƙarfe na lantarki (tsarki fiye da 99.7%, kauri 5um-105um) yana ɗaya daga cikin kayan asali na masana'antar lantarki. Ci gaban masana'antar bayanai ta lantarki cikin sauri, amfani da takardar jan ƙarfe ta lantarki yana ƙaruwa, ana amfani da samfuran sosai a cikin kalkuleta na masana'antu, kayan aikin sadarwa, kayan aikin QA, batirin lithium-ion, talabijin na farar hula, na'urorin rikodi na bidiyo, na'urorin rikodi na CD, na'urorin kwafi, waya, na'urar sanyaya iska, na'urorin lantarki na mota, na'urorin wasan bidiyo.

Tagulla mai masana'antuza a iya raba shi zuwa rukuni biyu: foil ɗin jan ƙarfe da aka naɗe (foil ɗin jan ƙarfe na RA) da foil ɗin jan ƙarfe mai maki (foil ɗin jan ƙarfe na ED), wanda foil ɗin jan ƙarfe na kalanda yana da kyakkyawan aiki da sauran halaye, shine farkon aikin farantin laushi da aka yi amfani da shi foil ɗin jan ƙarfe, yayin da foil ɗin jan ƙarfe na electrolytic yana da ƙarancin farashi na ƙera foil ɗin jan ƙarfe. Kamar yadda foil ɗin jan ƙarfe mai birgima muhimmin abu ne na allon laushi, don haka halayen foil ɗin jan ƙarfe na kalanda da canje-canjen farashi a masana'antar allon laushi suna da wani tasiri.

Mene ne ƙa'idodin ƙira na asali na jan ƙarfe a cikin PCB?

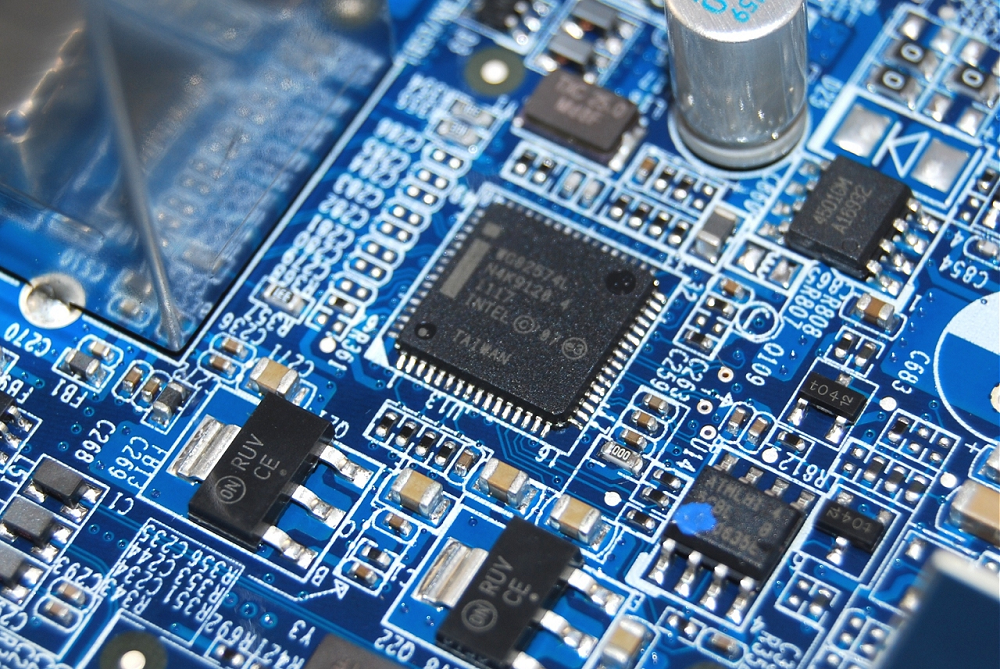

Shin kun san cewa allon da'ira da aka buga suna da yawa a cikin rukunin kayan lantarki? Ina da tabbacin akwai ɗaya a cikin na'urar lantarki da kuke amfani da ita a yanzu. Duk da haka, amfani da waɗannan na'urorin lantarki ba tare da fahimtar fasaharsu da hanyar ƙira ba shi ma abu ne da aka saba yi. Mutane suna amfani da na'urorin lantarki kowace awa ɗaya amma ba su san yadda suke aiki ba. Don haka ga wasu manyan sassan PCB waɗanda aka ambata don fahimtar yadda allon da'ira da aka buga ke aiki cikin sauri.

· Allon da'ira da aka buga allon filastik ne mai sauƙi tare da ƙarin gilashi. Ana amfani da foil ɗin jan ƙarfe don bin diddigin hanyoyin kuma yana ba da damar kwararar caji da sigina a cikin na'urar. Alamun jan ƙarfe sune hanyar samar da wutar lantarki ga sassa daban-daban na na'urar lantarki. Maimakon wayoyi, alamun jan ƙarfe suna jagorantar kwararar caji a cikin PCBs.

· PCBs na iya zama layi ɗaya da kuma layuka biyu suma. PCB mai layi ɗaya shine mafi sauƙi. Suna da foiling na jan ƙarfe a gefe ɗaya kuma ɗayan gefen shine ɗakin sauran sassan. Yayin da suke kan PCB mai layi biyu, ɓangarorin biyu an tanada su don foiling na jan ƙarfe. PCBs masu layi biyu sune PCBs masu rikitarwa waɗanda ke da alamun rikitarwa don kwararar caji. Babu foil ɗin jan ƙarfe da zai iya ratsa juna. Ana buƙatar waɗannan PCBs don na'urorin lantarki masu nauyi.

· Akwai kuma layuka biyu na solders da silkscreen a kan jan ƙarfe PCB. Ana amfani da abin rufe fuska na solder don bambanta launin PCB. Akwai launuka da yawa na PCBs da ake da su kamar kore, shunayya, ja, da sauransu. Abin rufe fuska na solder kuma yana ƙayyade jan ƙarfe daga sauran ƙarfe don fahimtar sarkakiyar haɗin. Duk da cewa silkscreen shine ɓangaren rubutu na PCB, ana rubuta haruffa da lambobi daban-daban akan silkscreen don mai amfani da injiniya.

Yadda ake zaɓar kayan da ya dace don jan ƙarfe a cikin PCB?

Kamar yadda aka ambata a baya, kuna buƙatar ganin hanyar mataki-mataki don fahimtar tsarin ƙera allon da'ira da aka buga. Ƙirƙirar waɗannan allon suna ɗauke da matakai daban-daban. Bari mu fahimci wannan tare da jerin:

Kayan ƙasa:

Tushen tushe a kan allon filastik da aka yi amfani da gilashi shi ne substrate. Substrate tsarin dielectric ne na takarda wanda yawanci aka yi da resin epoxy da takardar gilashi. An ƙera substrate ta yadda zai iya biyan buƙatun misali yanayin zafi na canzawa (TG).

Lamination:

Kamar yadda aka bayyana daga sunan, lamination kuma hanya ce ta samun abubuwan da ake buƙata kamar faɗaɗa zafi, ƙarfin yankewa, da zafi na canzawa (TG). Lamination ana yin sa ne a ƙarƙashin matsin lamba mai yawa. Lamination da substrate tare suna taka muhimmiyar rawa a cikin kwararar caji na lantarki a cikin PCB.

Lokacin Saƙo: Yuni-02-2022