Fayil ɗin Tagulla na RA

Tagulla foil C5191/C5210

Tagulla abu ne da aka yi da ƙarfe ta hanyar narkar da jan ƙarfe tare da wasu ƙarfe masu daraja ko na musamman. Haɗuwa daban-daban na ƙarfe suna da halaye daban-daban na zahiri da kumaaikace-aikaceAn samar da foil ɗin tagulla ta hanyarCIVEN METAL galibin su ne foils na tagulla da tin-phosphor, waɗanda ke ɗauke da babban sinadarin jan ƙarfe, tin da phosphorus.Yana da waɗannan siffofi:

1. Hƙara yawan phosphorus da kuma ƙarfin gajiya mai kyau.

2. Better elasticity da juriya ga lalacewa.

3, Nmai amfani da maganadisu, tare da kyawawan halayen injiniya da fasaha

4, Cjuriyar orrosion, ana iya haɗa shi da kyau kuma a yi masa bracing, babu tartsatsin wuta a kan tasiri.

5, Gwutar lantarki mai amfani da wutar lantarki, ba ta da zafi cikin sauƙi don tabbatar da aminci.

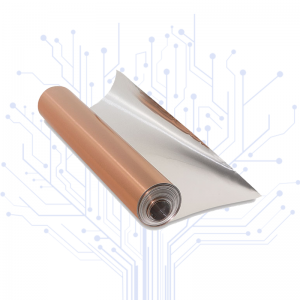

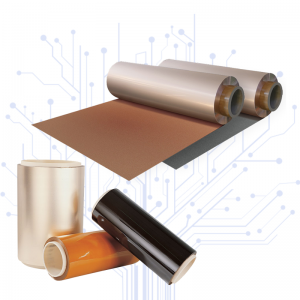

Saboda halayensa na musamman na aiki, ana amfani da foil ɗin tagulla sau da yawa don ƙera nau'ikan kayan lantarki daban-daban, simintin da ba ya shiga iska, masu haɗawa, kayan da ba sa jure lalacewa don kayan aiki masu inganci.An birgima takardar tagulla dagaCIVEN METAL kuma yana da sauƙin gyarawa da laminate, kuma yana da sauƙin gyarawa.Saboda siffar siffar ƙwallotsari na birgimatagulla foil, yanayin laushi da tauri za a iya sarrafa shi ta hanyar tsarin rage zafi, wanda hakan ya sa ya fi dacewa da nau'ikan aikace-aikace.CIVEN METAL kuma tana iya samar da foils na tagulla a cikin kauri da faɗi daban-daban bisa ga buƙatun abokin ciniki, don haka rage farashin samarwa da inganta ingancin sarrafawa.

Sinadaran da ke cikinsa (%)

| Lambar ƙarfe | Yawan yawa (g/cm³) | Sn | P | Cu | |

| China | Japan | ||||

| Qsn6.5-0.1 | C5191 | 8.83 | 6.0-7.0 | 0.1-0.25 | 93.3 |

| Qsn8-0.3 | C5210 | 8.0 | 7.0-9.0 | 0.03-0.25 | 91.9 |

Kayayyakin Inji (Misali: GB/T5189-1985)

| Lambar Alloy | JIS Temper | Ƙarfin Tafiya Rm/N/mm 2 | Ƙarawa(%) | HV Temper |

| C5191 | O | 315 | 40 | -- |

| 1/4H | 390-510 | 35 | 100-160 | |

| 1/2H | 490-610 | 20 | 150-205 | |

| H | 590-680 | 8 | 180-230 | |

| EH | 630 | 5 | 210-230 | |

| C5210 | 1/2H | 470-610 | 27 | 140-205 |

| H | 590-705 | 20 | 185-235 | |

| EH | 680-780 | 11 | 205-230 | |

| SH | 735-835 | 9 | 230-270 |

Lura:Za mu iya samar da kayayyaki tare da wasu kadarori bisa ga buƙatun abokan ciniki.

Bayanan da ake da su (mm)

| Kauri | Faɗi | Mai halin ɗaci |

| 0.01 ~ 0.15 | 4.0~650 | An keɓance |

Girman da Juriya (mm)

| Kauri | Juriyar Kauri | Faɗi | Juriyar Faɗi |

| 0.01 ~ 0.6 | ± 0.002 | 4.0~650mm | ± 0.1 |

| >0.06 ~ 0.15 | ± 0.003 |