Allon da'ira mai sassauƙa da aka buga nau'in allon da'ira ne da ake iya lanƙwasawa saboda dalilai da yawa. Fa'idodinsa akan allunan da'ira na gargajiya sun haɗa da rage kurakuran haɗuwa, kasancewa mai juriya a cikin yanayi mai wahala, da kuma iya sarrafa saitunan lantarki masu rikitarwa. Ana yin waɗannan allunan da'ira ta amfani da foil ɗin jan ƙarfe na electrolytic, wani abu da ke tabbatar da cewa yana ɗaya daga cikin mafi mahimmanci a masana'antar lantarki da sadarwa.

Yadda Ake Yin Lankwasa Da'irori

Ana amfani da na'urorin lantarki masu lankwasawa a cikin na'urorin lantarki saboda dalilai daban-daban. Kamar yadda aka fada a baya, yana rage kurakuran haɗawa, yana da juriya ga muhalli, kuma yana iya sarrafa na'urorin lantarki masu rikitarwa. Duk da haka, yana iya rage farashin aiki, rage nauyi da buƙatun sarari, da kuma rage wuraren haɗin kai waɗanda ke ƙara kwanciyar hankali. Saboda duk waɗannan dalilai, na'urorin lantarki masu lankwasa suna ɗaya daga cikin sassan lantarki da ake buƙata a masana'antar.

A da'irar bugawa mai sassauƙaya ƙunshi manyan sassa uku: Masu jagoranci, Mannewa, da Masu Rufewa. Dangane da tsarin da'irar lanƙwasa, waɗannan kayan guda uku an shirya su ne don kwararar wutar lantarki ta yadda abokin ciniki yake so, kuma don ya yi mu'amala da wasu kayan lantarki. Mafi yawan kayan da ake amfani da su don mannewar da'irar lanƙwasa sune epoxy, acrylic, PSAs, ko wani lokacin babu su, yayin da masu rufewa da aka saba amfani da su sun haɗa da polyester da polyamide. A yanzu, muna da sha'awar masu kwantar da wutar lantarki da ake amfani da su a waɗannan da'irori.

Duk da cewa ana iya amfani da wasu kayan aiki kamar azurfa, carbon, da aluminum, amma kayan da aka fi amfani da su wajen sarrafa wutar lantarki shine jan ƙarfe. Ana ɗaukar foil ɗin jan ƙarfe a matsayin muhimmin abu don kera da'irori masu lanƙwasa, kuma ana samar da shi ta hanyoyi biyu: na'urar jujjuyawa ko kuma electrolysis.

Yadda Ake Yin Takardun Tagulla

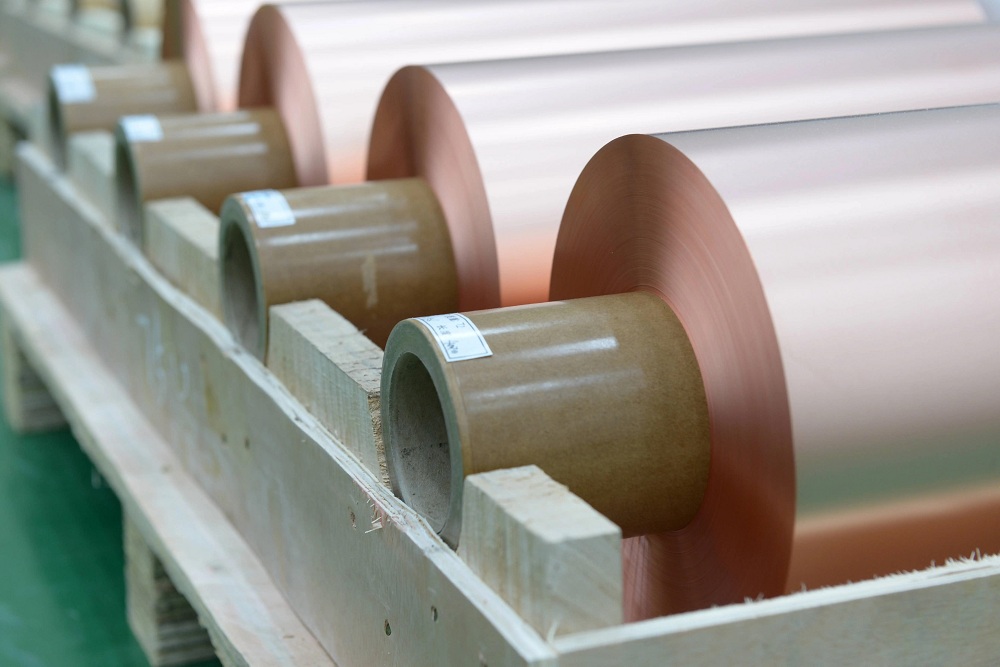

Takardar jan ƙarfe mai birgimaAna samar da shi ta hanyar birgima zanen tagulla mai zafi, rage su da kuma samar da saman jan ƙarfe mai santsi. Ana fuskantar matsanancin zafi da matsin lamba ta hanyar wannan hanyar, wanda ke samar da santsi da kuma inganta sassauci, lanƙwasawa, da kuma watsawa.

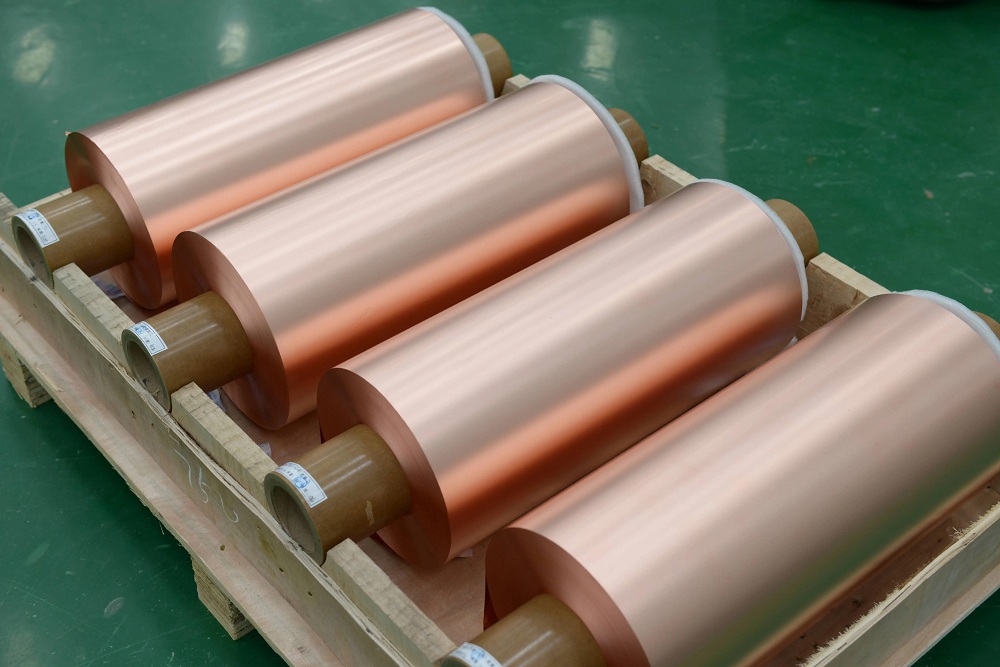

A halin yanzu,jan ƙarfe mai amfani da electrolytic foiAna samar da l ta hanyar amfani da tsarin electrolysis. Ana ƙirƙirar maganin jan ƙarfe da sinadarin sulfuric acid (tare da wasu ƙarin abubuwa dangane da ƙayyadaddun masana'anta). Sannan ana gudanar da ƙwayar electrolytic ta cikin maganin, wanda hakan ke sa ions na jan ƙarfe su zube su faɗi a saman cathode. Haka kuma ana iya ƙara ƙarin abubuwa a cikin maganin wanda zai iya canza halayensa na ciki da kuma bayyanarsa.

Wannan tsari na electroplating yana ci gaba har sai an cire ganga mai kauri daga cikin ruwan. Gangar kuma tana sarrafa kauri na jan ƙarfen da za a yi amfani da shi, domin ganga mai sauri yana jawo ƙarin ruwan sama, yana ƙara kauri na farantin.

Ko da kuwa wace hanya ce, duk foil ɗin jan ƙarfe da aka samar daga waɗannan hanyoyin guda biyu za a ci gaba da yi musu magani da maganin haɗin gwiwa, maganin juriyar zafi, da kuma maganin kwanciyar hankali (anti-oxidation) bayan an gama amfani da su. Waɗannan magungunan suna ba foil ɗin jan ƙarfe damar ɗaurewa da mannewa da kyau, su fi juriya ga zafin da ke tattare da ƙirƙirar da'irar bugawa mai sassauƙa, da kuma hana iskar shaka ta foil ɗin jan ƙarfe.

An yi birgima da Annealed vs Electrolytic

Domin kuwa tsarin ƙirƙirar takardar jan ƙarfe ta amfani da takardar jan ƙarfe mai birgima da kuma takardar jan ƙarfe mai amfani da lantarki ya bambanta, suna kuma da fa'idodi da rashin amfani daban-daban.

Babban bambanci tsakanin foil ɗin jan ƙarfe guda biyu shine dangane da tsarinsu. Foil ɗin jan ƙarfe mai birgima zai sami tsari a kwance a yanayin zafi na yau da kullun, wanda daga nan zai canza zuwa tsarin lu'ulu'u mai lamellar idan aka fuskanci matsin lamba da zafin jiki mai yawa. A halin yanzu, foil ɗin jan ƙarfe mai amfani da electrolytic yana riƙe da tsarin ginshiƙinsa a yanayin zafi na yau da kullun da kuma matsin lamba mai yawa da yanayin zafi.

Wannan yana haifar da bambance-bambance a cikin ikon amfani da wutar lantarki, juriya, lanƙwasawa, da kuma farashin nau'ikan foil ɗin jan ƙarfe guda biyu. Saboda foil ɗin jan ƙarfe da aka naɗe gabaɗaya suna da santsi, suna da ƙarfin amfani da wutar lantarki kuma sun fi dacewa da ƙananan wayoyi. Hakanan suna da ƙarfin aiki kuma gabaɗaya suna da sauƙin lanƙwasawa fiye da foil ɗin jan ƙarfe na lantarki.

Duk da haka, sauƙin hanyar electrolysis yana tabbatar da cewa foil ɗin jan ƙarfe na electrolytic yana da rahusa fiye da foil ɗin jan ƙarfe na annealed. Amma ku lura cewa ba su da kyau ga ƙananan layuka, kuma suna da juriya mai lanƙwasa fiye da foil ɗin jan ƙarfe na annealed.

A ƙarshe, foil ɗin jan ƙarfe na electrolytic zaɓi ne mai kyau mai rahusa a matsayin masu jagoranci a cikin da'irar bugawa mai sassauƙa. Saboda mahimmancin da'irar lanƙwasa a cikin kayan lantarki da sauran masana'antu, hakan kuma yana sanya foil ɗin jan ƙarfe na electrolytic ya zama muhimmin abu.

Lokacin Saƙo: Satumba-14-2022